Maintenance and revamping of Waste Incineration Plant furnaces. Since 1985 we provide expertise, consulting and periodic maintenance of your industrial equipment and especially revamping of WTE plant furnaces to optimize the resistance and R.O.I. of grate bars.

Through Skills of our teams we can offer an extensive range of services from scheduled maintenance to a full service contract by passing emergency repairs.

We are located in Marquise, North of France. This ideal location, easy-to-access, allows us to benefit from main European routes, by sea, train or road in shortest time.

The quality of service

We assure:- expertise

- the organization of interventions: spare parts, human, technical, coordination

- personalized maintenance plan

- capitalization of interventions in order to retain traceability of the installation

- Hopper: thickness control, replacing shielding

- Valve / Lock: replacement bearings, plates

- Push (Worm / drawer): Replacement bearings, sheet metal, welding

- Grate: Replacement bars, banks

- Bottom Grate: Replacement balls, wheels, truck

- Box under grid: casing control, weld sealing

- Hopper end grates: control casing, sealing seams

- Puller (swing / with chain / screw): chain links, scrapers, sheets

- Fluidized bed: Replacement nozzles

- Multi - cyclone: Control, replacement cones

We can serve you both ways

If you have maintenance team- We offer grate bars + supervision if needed

- We take care of service & maintenance + provide necessary grate bars

Service From start to finish

We support you, once the maintenance done, by giving you an intervention report that specifies the operations, replaced elements and their statements prior interventions. We also inform you of the monitored components, parts that require next maintenance or replacement items for technical improvements that may be offered. In the context for a full service contract, we ensure, to your date, all of the operations. We provide, according to your stock and future interventions, the spare parts needed.

Engineers are innovative day after day, don not hesitate to contact us to benefit of last solutions and advices. Saretco creates quotes to suit your needs.

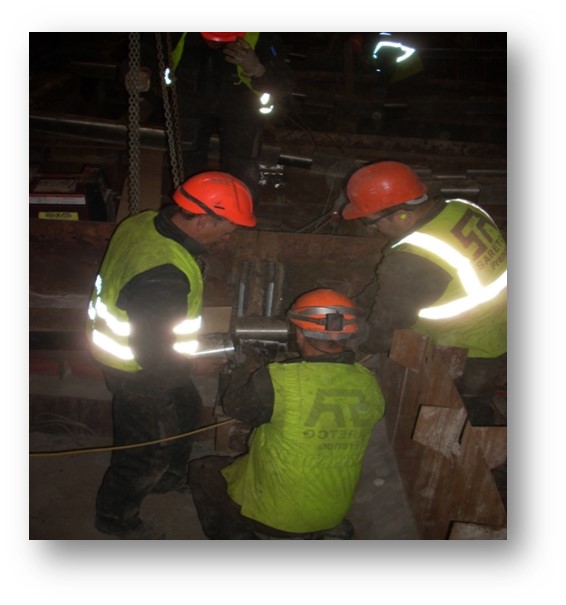

How we work during maintenance

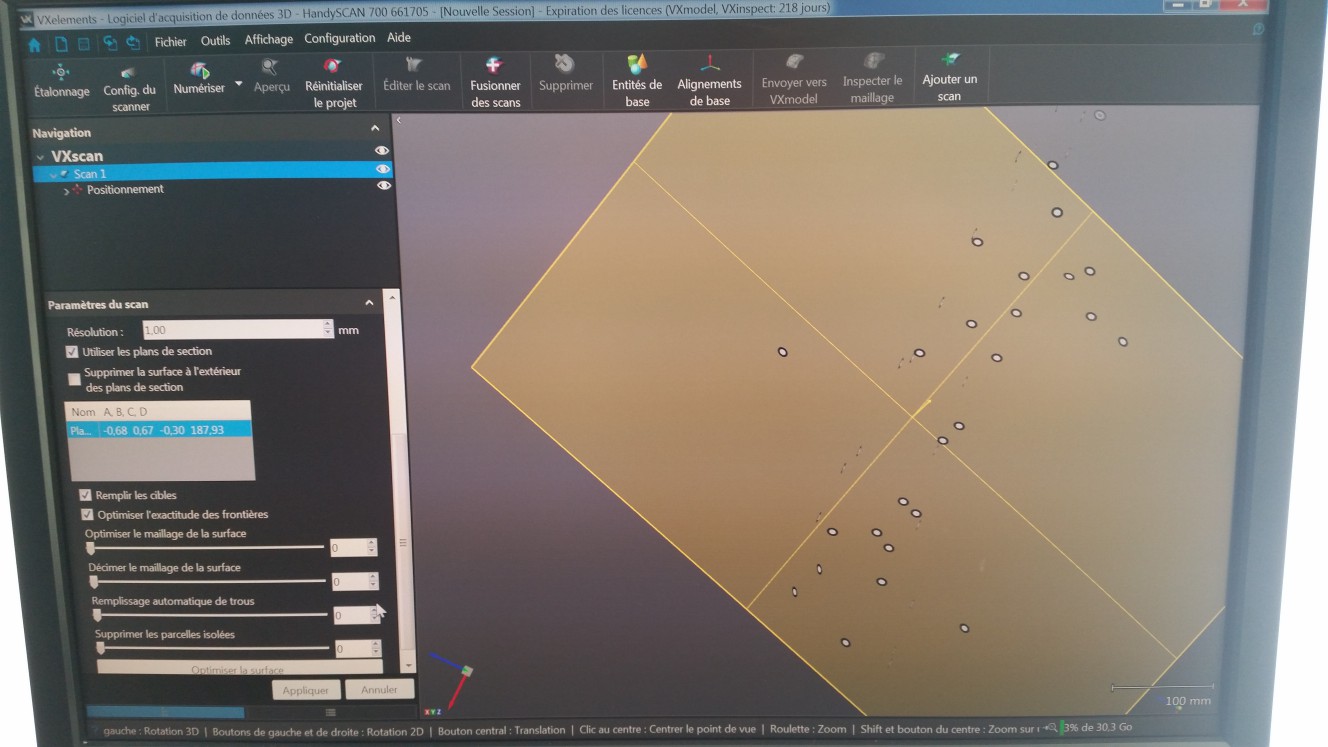

We do expertise of your plant

Setting up requirements for solutions and spares

Preparation of financial proposal and reconciliation

Maintenance and revamping works in cooperation with plant operator

Test and additional expertise

After execution of revamping - setting up after-sales plan