- Constant evolution of the waste composition reveals lot of new constraints which lead customers to use best in class technologies to solve those issues.

- Each WTE plant has unique specifications. Permanent discussion between Plant Managers, who face those constraints on a daily basis, and our R&D Department is the only way to jointly come up with design of a new well-adapted solution.

SARETCO designs, manufactures and provides incineration furnace grates maintenance since 1985

- SARETCO TEAM benefits from long experience in usage of super-alloys resistant to corrosion, oxydation and abrasion at high temperatures.

- SARETCO KNOW-HOW is based on expertise of more than 140 incinerator plants, all furnace and fuel types.

- SARETCO MATERIAL has been tested and validated by trials during on-site operations, in partnership with european key-players (VEOLIA, SITA, DONG ENERGY, …).

- SARETCO CONSTANT INNOVATION is based on a strong presence of our engineers on the ground, and extended exchanges with plant operators.

- MOTIVATION of SARETCO, leader on furnace grate market, is to design and promote its own furnace together with additional partners as part of EPC contracts (HITACHI INOVA, CNIM, VINCI, FABRICOM/SUEZ).

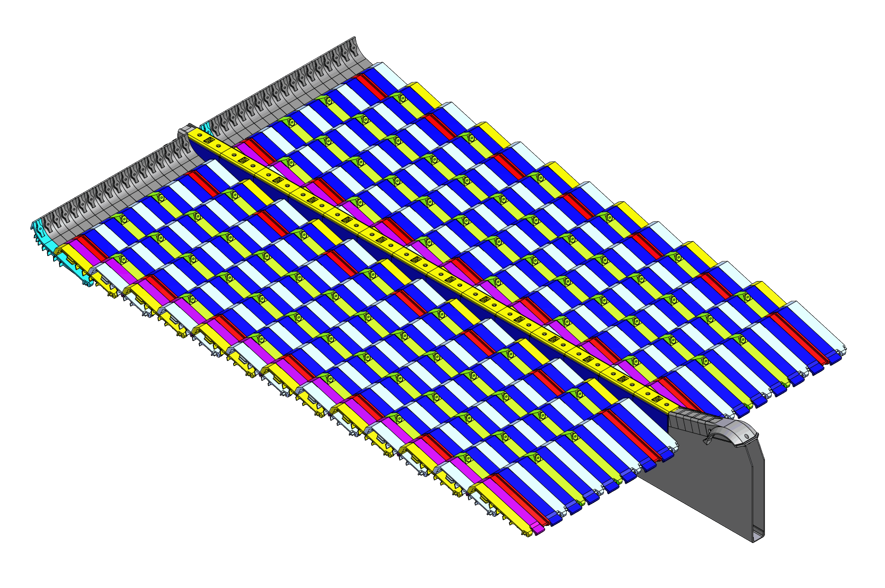

- Sar3 Grate System

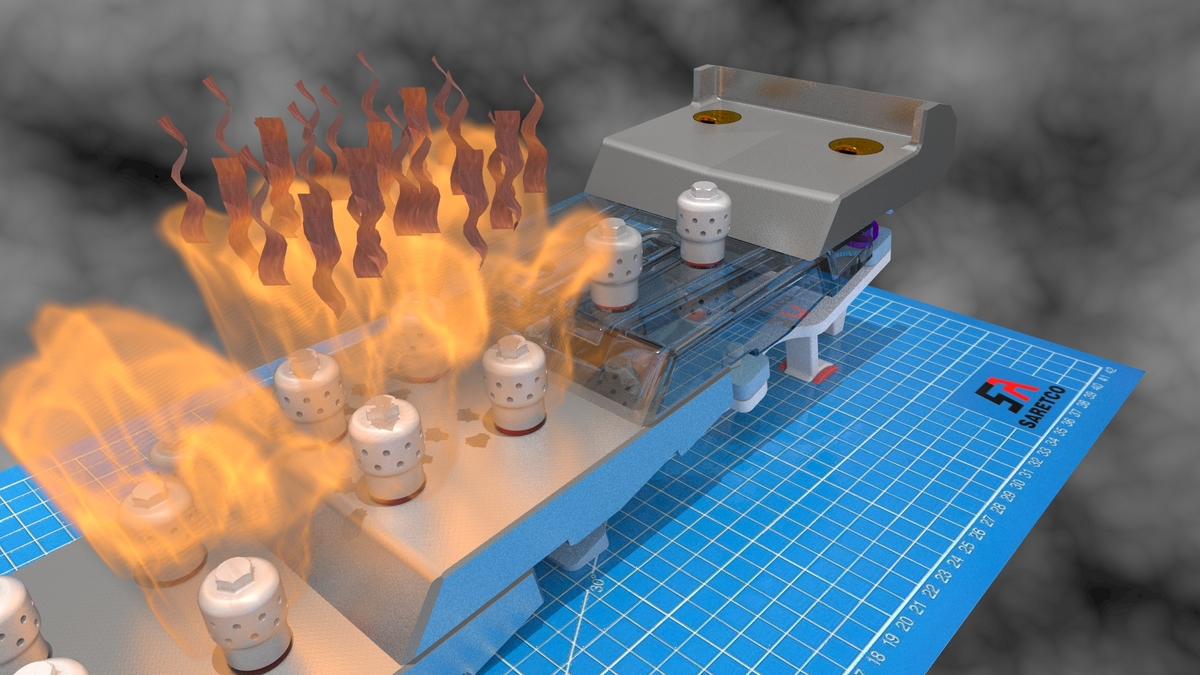

- Sar 3 s - Fluidised Bed Furnace On Grate

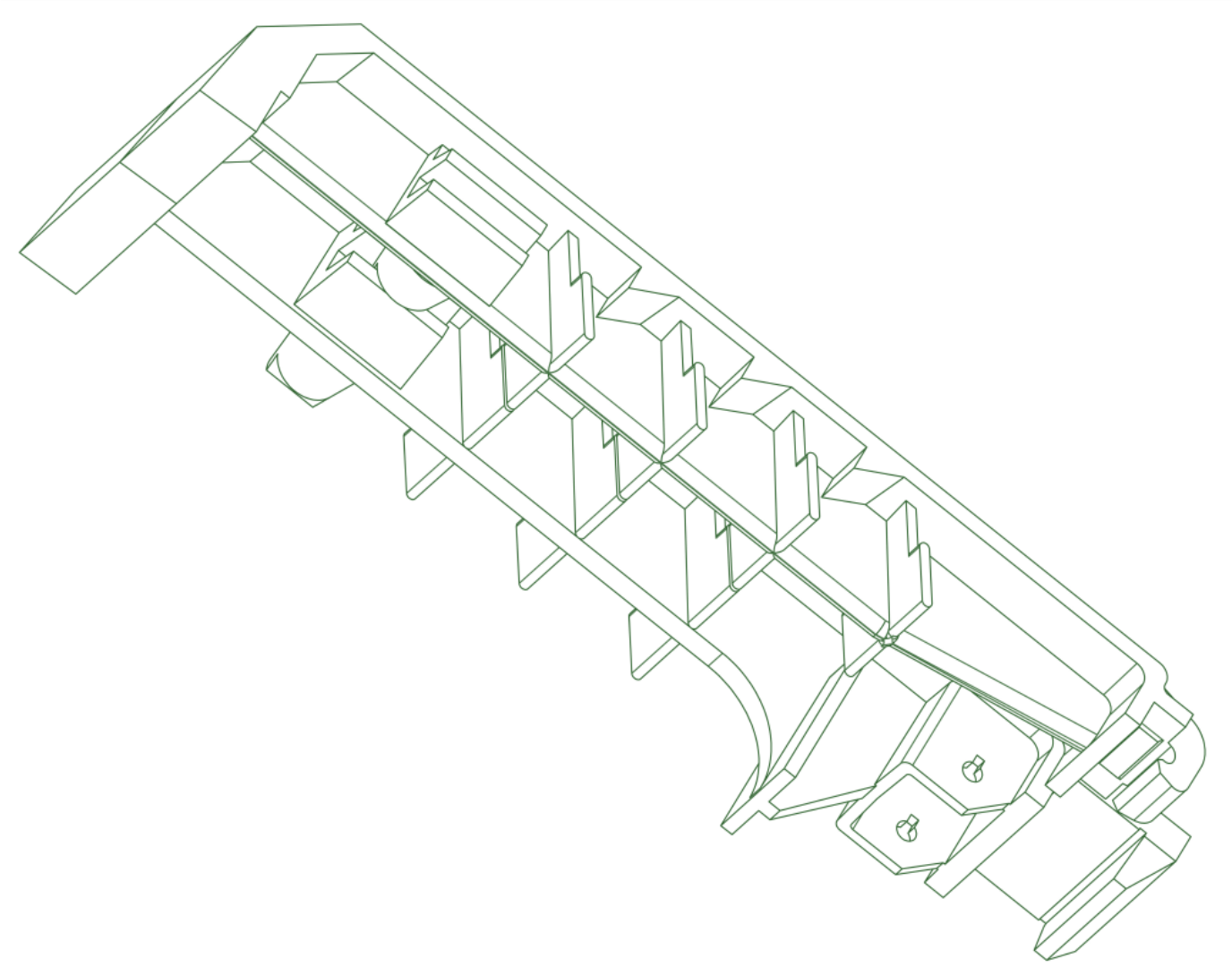

- BIMETAL Grate Bars

- SAR2 Grate Bars

Ways to control combustion

Saretco shows us that it is possible to control combustion even that this is possible, whatever the products being treated, 3 questions arise:

- What does combustion control look like?

- Why are we trying to control it?

- What would the consequences be of poor combustion control?

The control of combustion requires taking into account parameters not only from technical engineering, but also from mechanical and metallurgical engineering

- Firstly, with grating expertise.... for the treatment of urban waste or biomass

- Studies to upgrade grates.... to enable furnaces to process solid objects

- Optimisation through analysis.... of combustive air flows

- Refurbishment and maintenance with full warranty

- Parts manufacturing for spares for any type of grate, with more than 3 million in stock.

These parameters are not sufficient to achieve efficient combustion. Saretco stands out thanks to its perfect knowledge of the problems products to be treated can cause, problems which change according to our consumption mode. Since the date of its creation, Saretco has faced the exponential incineration technology, whose main objective is to bring some value to waste.

First burning

- Products made of coal ash... bottles of scrap metal and putrescible waste with a heating value between 1,600 to 1,800 kilo calories per kilo. The problems encountered at that time were limited only to wear by abrasion and breaking of bars.

- Next, with the massive influx of plastic packaging polystyrene aluminium boxes and hospital waste carried the average heating value to 1,800 to 2,200 kilo calories.

- Finally, with the emergence of selective sorting and then grinding waste with the addition of dried sludge and CSR, the calorific value increased from 2,700 kilo calories to 3,500 kilo calories generating damage on manufacturer grates designed to burn waste producing a much lower calorific value thus generating exponential mechanical problems... deformations ....dilation ... abrasion ... corrosion, and ... rust thus causing a loss of energy due to bad combustion.

Therefore, grate upgrading studies became necessary to allow furnaces to process any solid product at maximum combustion optimisation and efficiency, while meeting the requirements of European regulations. A well-made grate allows for a saving on maintenance.

Learn more about Saretco's patented products:

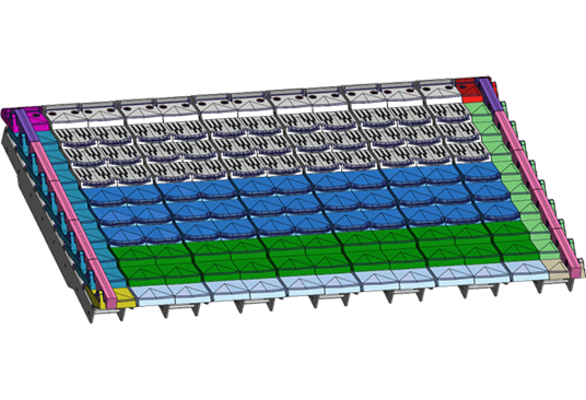

The main benefits with the new SARETCO SAR3 grate composed of patented grate bars

Modular fluidized bed on grate furnace to treat biomass and special waste in dedicated plants : for example the Solid Recovered Fuel with high LHV.

Saretco proposes Bimetal grate bar in substitution to the OEM watercooled grate bar, giving equal lifetime with easiest handling and maintenance.

The special shapes of the ribs allows, by assembling 2 grates bars, to create a channel which canalize the combustible-air