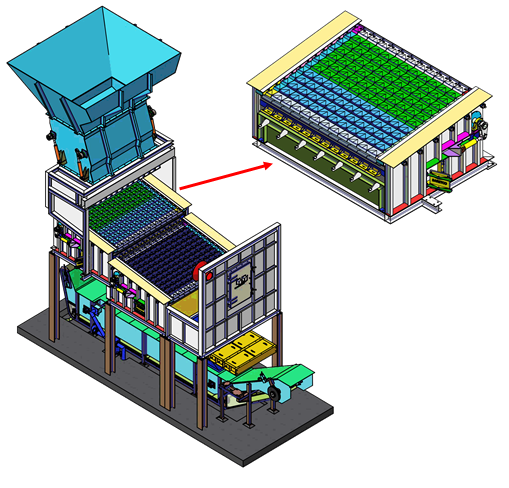

The SARETCO type SAR3 furnace, installed at 26 sites across Europe, makes it possible to deal more effectively with the current problems of incineration such as with the evolution of the composition of waste. Its innovative technology and its carefully considered metallurgy make it possible to burn waste with high LHV (up to 3500 KJ per KG including CSR, sludge, DH, DIB, etc.) without encountering any common problems such as deformations or premature wear.

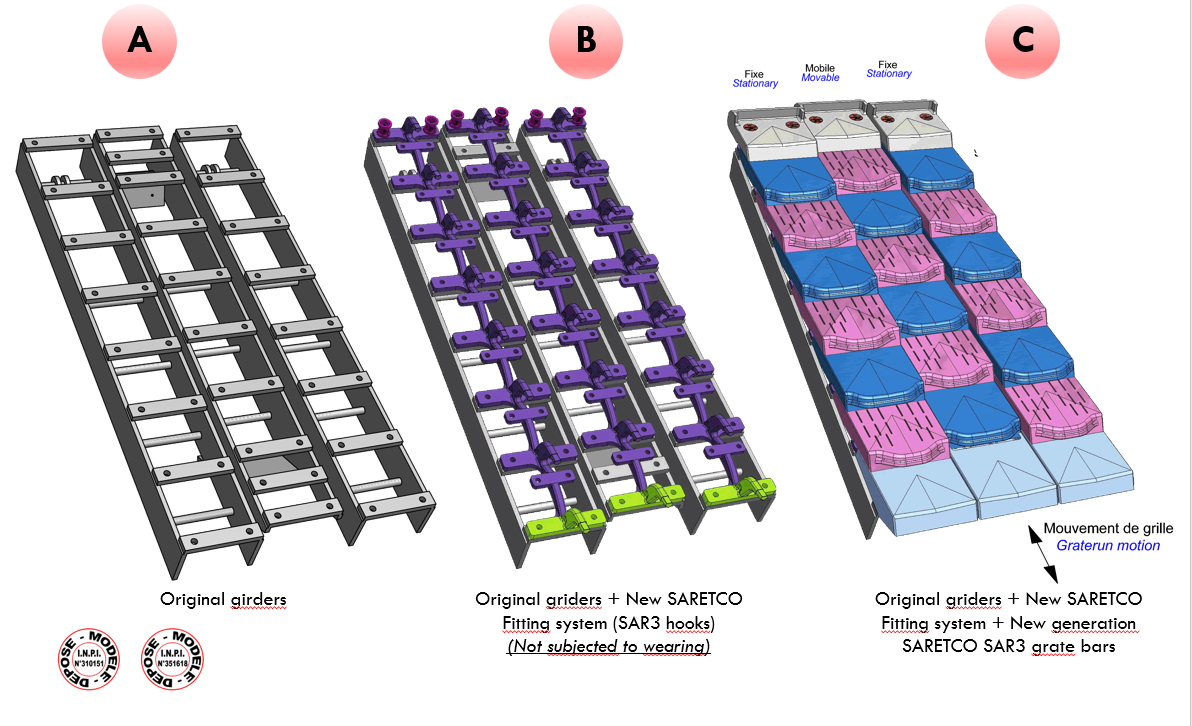

The main benefits with the new SARETCO SAR3 grate composed of patented grate bar

Improved grate performance- Oriented and controlled combustive primary air flow

- Strong reduction of both aluminum and fines underneath

- Permanent pressure applied on the grate by our patented spring system

- Much finer ashes and Cr6 reduction

- Usually, nominal load capacity increased by approx. 10%

- Only grate bars in contact with fuel have to be replaced from the 2nd fitting; material cost is about 10% cheaper than a standard grate

- Assembly and disassembly by clamping and fixing with bolts accessible from top of the grate; time for intervention approximately 30% faster than a standard grate